WS Flex

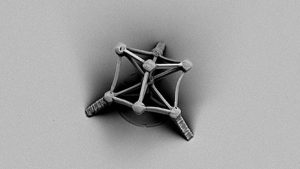

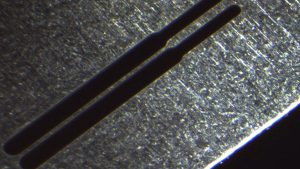

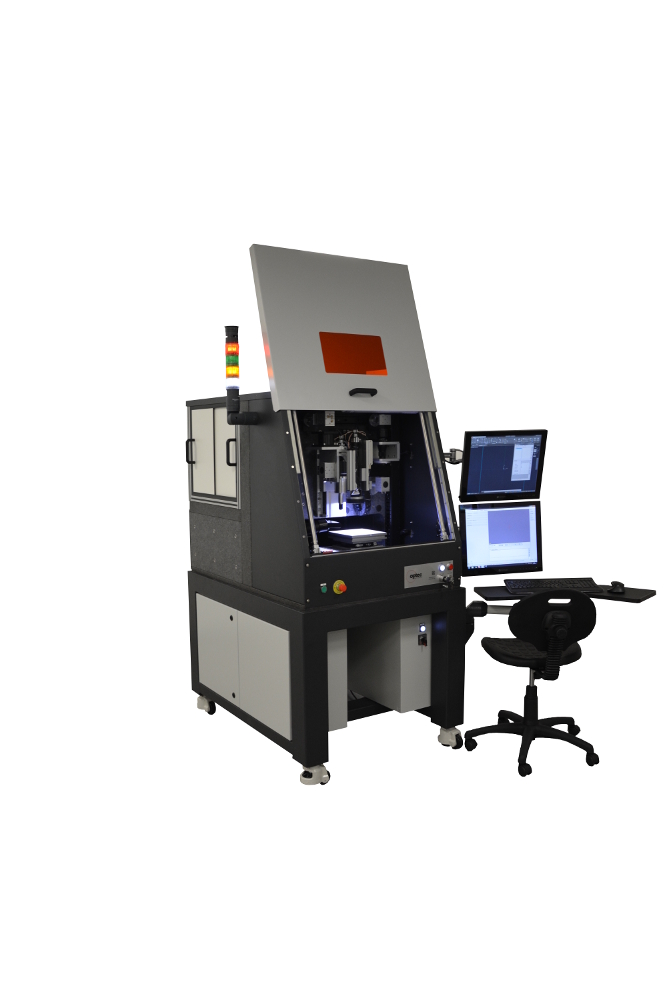

The WS FLEX is our flagship focal-point laser micro-machining system designed for high throughput, production use. The WS FLEX is be powered by a wide selection of compact focal-point lasers including femtosecond, picosecond, DPSS YAG and fiber lasers that are integrated in the enclosure for self-contained, turnkey operation and a small, footprint. Its CLASS 1 safety enclosure with pneumatic-actuated part loading/unloading door is fully covered and interlocked.

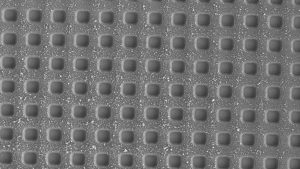

The WS-FLEX is equipped with HD zoom video microscope with optional pattern recognition software (PRS) for automatic alignment and inspection; 300 x 300 mm sub-micron resolution XY stages with vacuum chuck, high-speed scan head with infinite-field-of-view (IFOV) stage synchronized motion control or fixed focus cutting head with Optec’s proprietary gas shield / debris management nozzle, integrated industrial PC including touch-screen displays, among many other standard and optional features.

A welded steel frame with isolated and dampened, granite optical bed plus purged beam path ensures years of reliable operation and consistent results with minimal maintenance.

Specifications

- Wavelength (nm)

- 1064/1030,532/515 or 355/343

- Machining head

- Galvo scanner, fixed lens, cutting head

- Laser type (pulse duration)

- Nanosecond, picosecond, femtosecond

- Max. Scanner field (if applicable)

- Up to 90x90 mm²

- Minimum Spot size

- <5 µm

- XY stages travel

- 200x200 mm

- Outer dimensions in mm (HxWxD)

- 2250x890x1250

- Common options

- Rotary stages, Tube lathe, Fume extraction